RAILWAY TRACKING SYSTEM

SWITCH POINT POSITION AND GAP MONITORING SYSTEM OVERVIEW

Rail Safety is one of the most important challenge we face on our day to day life. For the safety purpose, we have developed a system which will bring your railway system at any Switch Point. MachIndia's Switch Point Position Sensor provides to view the current status of a Rail Switch. We make use of the best technology in order to provide our clients with a solution that is Safe, Efficient, and Reliable.

Generally most of the rail accidents take place due to switch point errors are human attention issues, few of the accidents takes place due to minor spacing between the switch rail and the main rail which cause huge destruction. A Switch Point Position Sensor can help to diminish these accidents and not only save government property but also people's valuable life.

- 1. Easy and simple to install

- 2. When switch gap of relevant trains are above adequate amount, Real-time alerts are generated and sent to monitoring system

- 3. Onboard computer alerts the driver of switch gap issue

- 4. 24/7 monitoring of switch point

- 5. As switch gap issue is detected automatic braking is triggered.

BACKGROUND

Basically most of the rail accidents which are allocate to switch or switch point errors occured due to human attention issues, some of the accidents occured are due to minor spacing/gap between the switch rail and the main rail. In some cases, tampering of the switch has caused major accidents which results in heavy destruction. However, whether the rail switch generate accidents are attributed to human attention surplus or mechanical errors in switch closure, a sensor device has been electronically monitored the actual position of the switch point at each and every point and its gap which are communicated to both the monitoring center and oncoming trains with suitable automatic alerts and this control can reduce or eliminate many accidents and saves peoples life.

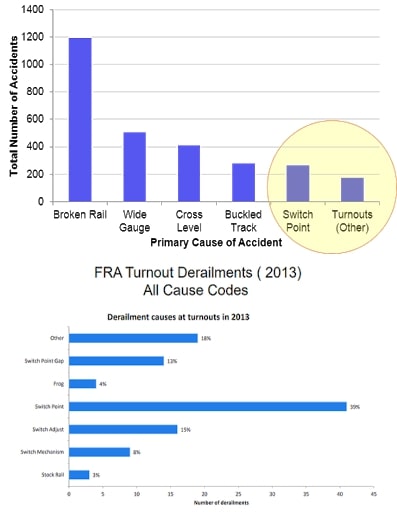

STATISTICS

By observing certain statistics, Turnouts cause 28% of all rail accidents and derailments which is a huge in number. While 40% or the majority of the derailments caused due to turnouts,which are due to switch point position errors in track. Other reason for accidents are Switch point gap and switch adjustment defects also cause 29% of the turnout derailments. All three of these problems can be resolved with an independent system/solution that can provide real-time and quantitative data for preventive maintenance which is benefecial for rail safety.

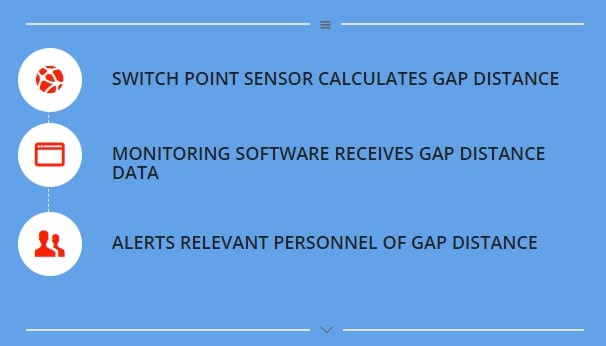

HOW IT WORKS…

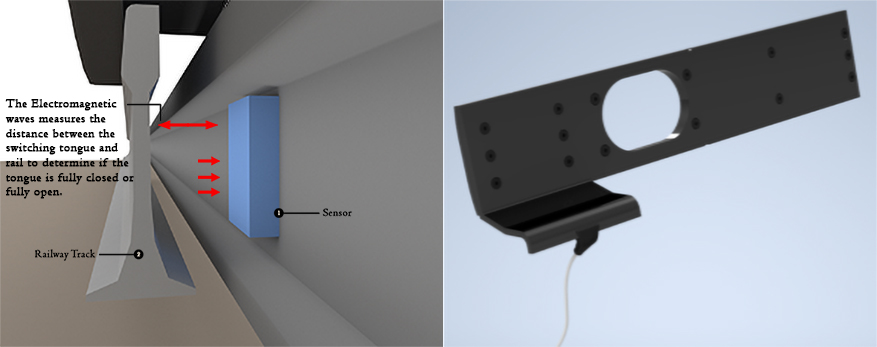

Magnetic Measurements

MACHINDIA's Switch Point Position Sensor works very well on magnetic measurements between the Switch Point Sensor and the Stock Rail, which lessen the accidents caused by derailments. By using the electromagnetic sensor, we are able to consider the distance between the Switch and Stock rails with finite precision. Even if something is blocking the sensor, the device will maintain an accurate recording of the switch gap which is one of the prominent feature of this system. The technique of measuring distance is highly accurate, minimal errors, and completely reliable and easy to use.

Rail switch position is intermesh with signaling as to the alignment of the turnout in correspondence to the oncoming train scheduled rail track. However, there is an absence of independent declaration of the switch point alignment to the oncoming train if there is an error.

MACHNINDIA's Switch Point Position and Gap Monitoring System includes the sensor unit and the electronic-communication module which is installed separately up to 10 meters away from the sensor unit (shown in figure). Here, the sensor module is installed on the stock rail and use electromagnetic wave for measuring quantitative proximity from zero to 50 mm of the switch point blade. Image is shown for your reference.

Real-Time Alert Reporting

MACHINDIA’s Switch Point Position Sensor working is basically based on magnetic measurements between the Switch Point Sensor and the Stock Rail. By using electromagnetic sensor, we are able to consider the distance between the Switch and Stock rails with finite correctness. One of the important feature of this system is, even if something is blocking the sensor, the device will maintain an accurate recording of the switch gap. This technique of measuring distance is proved to be highly accurate, minimal errors, and completely reliable.

CUSTOMIZABLE ALERTS AND AUTOMATIC BRAKE CONTROL

Switch point position is described and communicated in real-time to the Rail Control and Command Center as well as to the oncoming train to the switch point, which means sytem keep eyes on each and every activity. The position sensed by the unit is compared with the scheduled train track alignment for confirmation or alert of a variation.

1. MACHINDIA’s Rail Switch Point Monitoring Device generates alert for switch point incomplete closure error exceeding predefined safe spacing in real-time.

2. The switch point position data can be used in the central monitoring center and controls operation centrally, also directly assemblage with the onboard PTC control for real-time automatic alerts and control.

3. Spacing beyond zero between closed switch point and the stock rail is reported in real-time for determining changes over time and rate of change that may causes accidents if allowed to continue. In this way, preventive maintenance can be automatically scheduled.